Top Blast Room System Manufacturers in Pune - Balaji Shot Blasting Equipment

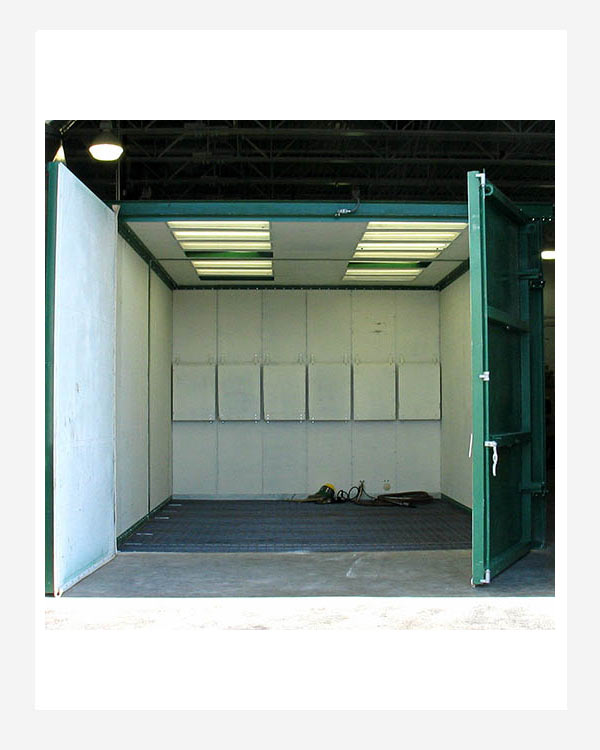

Balaji Shot Blasting Equipment is one of the leading Blast room Systems manufacturers, suppliers, exporters, and service providers in Pune, MH that provides high-end Blast Rooms Systems. Our quality abrasive blasting rooms also called sandblasting booths render the finest preparation of surfaces, which is administered in different ways such as cleaning, scaling and profiling.

Our shot blasting rooms enhance both efficiency and safety in terms of operations and the environment because of its strong system of dust collection and abrasive recovery. Our industrial blast rooms make excellent use of current technology which integrates high-quality ventilation technology with extremely efficient methods of energy consumption. Welcome to a discussion of the various models of blast room systems we have to offer along with the precise benefits they present and the various uses of surface preparation they are capable of!

Types of Abrasive Blast Room Systems

Being the best-used Blast room’s manufacturers and suppliers in Pune, MH, we focus on every processing step to get pure and high-quality Blasting in the end. Here we have listed down the process in detail:

Based on Construction

- Pre-Engineered Blast Rooms: These are normal-sized blast rooms comparable to a blast room and are appropriate in blasting any small and medium-sized items. They are also economically viable in values to general purposes.

- Pre-Assembled Blast Rooms: These rooms are relatively bigger than pre-engineered ones and most of them have full-floor abrasive media recovery systems. This saves on time wastage and cleaning.

- Engineered Blast Rooms: Make-to-order, to a particular application such as tank shops, vehicle shops or large parts, the rooms may be designed to accommodate such features as crane slot, cart tracks or drive-through facility. They are perfect in specialized and heavy-duty blasting purposes.

Based on Abrasive Recovery Systems

- Mechanical Recovery Systems: They comprise such mechanical systems as screw conveyors, bucket elevators, and separators to efficiently gather and reuse abrasive media, and so far as possible recover abrasive media and recycle it. They are appropriate to high volume and continuous activities.

- Vacuum Recovery Systems: In vacuum systems, air has been compressed to carry pole used abrasive to a recycling unit. These are commonly selected either in smaller installations or in cases where little noise and dust is needed.

Based on Automation

- Manual Blast Rooms: The blasting in the room is done manually by the operator under the safety gear. The arrangement is appropriate to low-volume or mixed components blasting.

- Automated Blast Rooms: Under such systems, blasting is carried out mechanically in a pre-programmed machine and as such minimizes the labor and improving consistency. They are best suited in repetitive blasting or high volume blasting.

Technical Specifications of our Industrial Blast Room System

| Parameter | Description |

|---|---|

| Features | Abrasive recovery and recycling system, Noise reduction measures |

| Material | Steel, Mild Steel |

| Built-Type | Modular, Prefab, Panel Build |

| Color | Multicolour, Blue |

| Brand | Vands, Innovus Engineering, Ram Blastek Equipment Pvt. Ltd |

| Frequency | 50 Hz |

| Height | 10 |

| Phase | Single |

| Voltage | 240V, 400V, 440V |

| Application | Industrial, Paint Removal, Rust Removal, Surface Finishing, Surface Cleaning |

Features and Benefits of using our blast room recovery system

As a premier Blast room system exporters and service providers in Pune, MH, we have used an advanced technological process in Shot Blasting Machine for smooth processing and providing excellent output such as:

- Noise Reduction Measures -The need to minimize noise is an important feature in designing and operating blast rooms to ensure their safety and comfort to operators as well as to ensure compliance with the industrial noise standards.

- Abrasive recovery and Re-cycling system- Constant Recovery & Recycling of the Abrasive System is probably among the most crucial aspect of any blast room, especially how the blasting processes are conducted in terms of efficiency, affordability, and environmental sustainability.

- Durable and Sturdy- The most critical factors taken into consideration in the design or building of any blast room would be the durability and the sturdiness since the room

Benefits of the Industrial Blast room System

- Controlled and consistent Results

- Enhanced Safety

- Environmental Responsibility

- Significant Cost savings

- Increased Productivity

- Dust Collection

- Abrasive recycling

- Reduced Exposure

- Reduced Outsourcing

Applications of Abrasive Blast Room Systems

- Surface Cleaning

- Coating Preparation

- Deburring

- Deflashing

- Surface Finishing

- Aesthetic Texturing

- Restoration of Old items

- Rust and Paint Paint Removal

- Aerospace

- Shipbuilding and Marine

- Automotive

- Defense and military

- Railways

- Heavy machinery

As a leading Blast rooms manufacturers, suppliers and exporters and services in Pune, MH ,we as Balaji Shot Blasting Equipment are committed to improving and maintaining the environmental sustainability of Blast rooms. These are made with new advanced technological updates for smoother processing and getting higher results. Contact us today for information!